A 90-degree elbow is a type of pipe fitting used in plumbing and piping systems. It’s designed to change the direction of the flow in a pipe by 90 degrees, creating a right angle turn.

This fitting is commonly used when piping needs to navigate around obstacles or change directions.

The 90-degree elbow can be either threaded or socket-welded, depending on the joining method used in the piping system. It’s essential to choose the appropriate size and material for the specific plumbing or piping application to ensure proper functionality and longevity.

| Name of the PDF | 90 degree elbow dimensions chart pdf |

| No. of pages | 1 |

| Category | Chart |

| Language | English |

| PDF Link | Click Here |

Also Download

Independent and Dependent Variables Worksheet With Answer Key PDF

What is a 90 Degree Elbow

A 90 degree elbow is an essential component in piping systems that are used to change the direction of flow. It is designed to create a 90-degree angle between the two connected pipes, allowing the fluid or gas to change direction smoothly.

These elbows are widely used in various industries and applications, such as plumbing, HVAC, oil and gas, chemical processing, and more. They are crucial for proper alignment and efficient flow in complex piping systems.

The 90 degree angle allows the pipes to turn perpendicularly to each other, ensuring a smooth transition without causing excessive turbulence, pressure drop, or flow restrictions. This ensures optimum flow performance and helps prevent any potential damage to the pipes or related equipment.

Common Applications of 90 Degree Elbows

A 90-degree elbow is a crucial component in piping systems and is widely used in various industries and applications. Here are some common applications where you’ll often find 90 degree elbows in use:

- Plumbing Systems: 90 degree elbows are commonly used in plumbing systems to change the direction of water flow. They are essential for connecting pipes at right angles, allowing for efficient routing and distribution of water. Whether it’s a residential building or a commercial facility, plumbing systems heavily rely on 90 degree elbows to ensure proper water flow.

- HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems require precise airflow management. 90 degree elbows play a vital role in directing air in the HVAC ductwork. By changing the direction of airflow, these elbows help optimize the performance of the system and ensure even distribution of conditioned air.

- Industrial Processes: In various industrial applications, 90 degree elbows are used to maintain the flow of liquids, gasses, or other materials. Industries such as chemical processing, oil and gas, power generation, and pharmaceuticals often utilize piping systems with 90 degree elbows to ensure the smooth movement of substances within the process.

- Construction Projects: The construction industry heavily relies on 90 degree elbows for plumbing and HVAC systems in residential, commercial, and industrial projects. These elbows are integral to connecting pipes and enabling efficient water and air flow in the built environment.

- Irrigation Systems: Another important application of 90 degree elbows is in irrigation systems. They are used to change the direction of water flow in agricultural fields, gardens, and landscapes. By properly aligning the pipes, 90 degree elbows enable efficient and effective irrigation practices.

- Marine and Shipbuilding: In the maritime industry, 90 degree elbows play a crucial role in maintaining the flow of fluids on ships and marine structures. These elbows ensure efficient routing and distribution of water, fuel, and other fluids required for various marine applications.

Types of 90 Degree Elbow

When it comes to 90 degree elbows, there are several variations available to suit different piping needs. Understanding the different types will help you make the right choice for your specific application. Here are some common types of 90 degree elbows:

- Short Radius Elbow: This type of elbow has a shorter radius, which means it has a tighter bend. Short radius elbows are ideal for applications where space is limited. They provide a smooth flow transition and are commonly used in tight corners and areas with restricted movement.

- Long Radius Elbow: Long radius elbows have a larger radius, allowing for a gentler bend. They are often used in applications where flow efficiency is crucial, as they help minimize friction and pressure drop. Long radius elbows are commonly seen in industrial processes and high-flow systems.

- Reducing Elbow: A reducing elbow is used when the pipe’s diameter needs to change within the elbow itself. It has different inlet and outlet sizes, allowing for a smooth transition between pipes of different sizes. Reducing elbows are commonly used in piping systems that require a change in flow direction and pipe size.

- Threaded Elbow: Threaded elbows have threaded ends, making them easy to connect to other threaded fittings. They are commonly used in plumbing systems and can be easily installed or removed when necessary. Threaded elbows ensure a secure and leak-free connection.

- Socket Weld Elbow: Socket weld elbows have a socket on one end, which allows them to be easily connected to pipes using fillet welds. They are typically used in high-pressure applications, such as in hydraulic systems or chemical plants, where a strong and secure joint is essential.

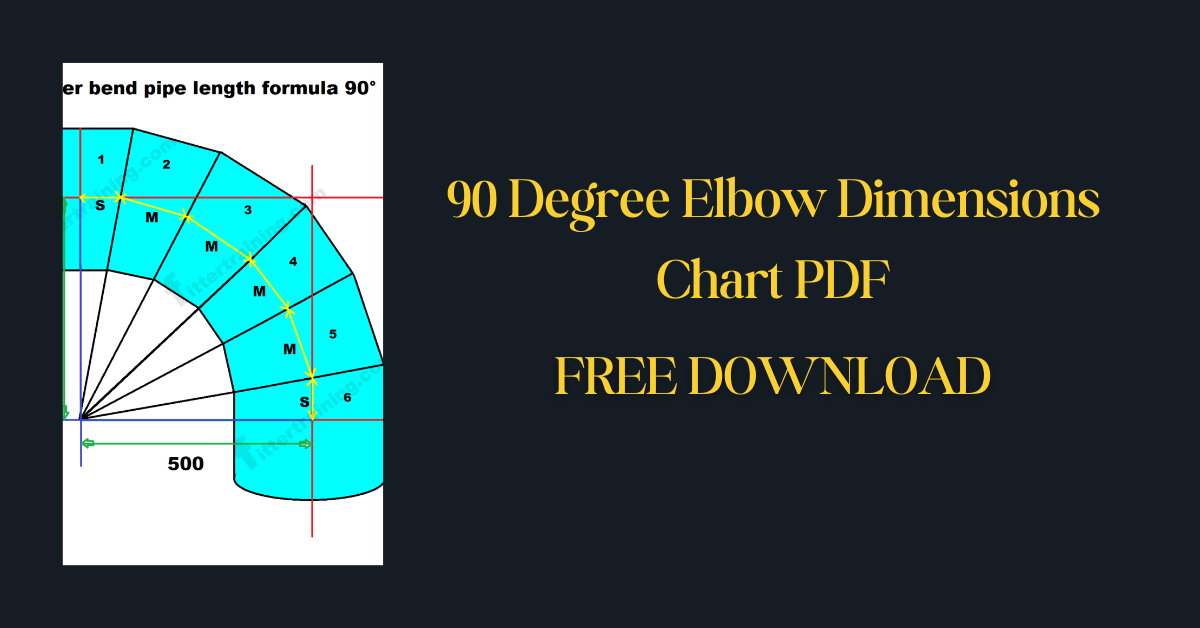

Understanding the Dimensions of a 90 Degree Elbow

When it comes to installing a 90 degree elbow in your piping system, understanding the dimensions is crucial. The dimensions of a 90 degree elbow determine its compatibility, fit, and overall effectiveness in your specific application.

Outside Diameter: The outside diameter of a 90 degree elbow refers to the measurement from one end of the elbow to the other, across the widest point. This dimension is important because it ensures that the elbow can be properly connected to the pipes in your system. It’s essential to select an elbow with the correct outside diameter to ensure a secure and leak-free connection.

Centerline Radius: The centerline radius of a 90 degree elbow is the measurement from the center of the elbow to the centerline of the arc. This dimension determines the smoothness of the bend in the elbow. A larger centerline radius provides a smoother flow transition, minimizing pressure drop and turbulence in the system. On the other hand, a smaller radius can be advantageous in applications with space constraints.

Wall Thickness: The wall thickness of a 90 degree elbow refers to the thickness of the elbow’s walls. This dimension is important for ensuring the structural integrity and durability of the elbow. It plays a crucial role in handling the pressure and flow requirements of your piping system. It’s essential to choose an elbow with the appropriate wall thickness to prevent flow restrictions or failure under high pressures.

Available sizes and materials

The size of an elbow plays a significant role in determining its compatibility and fit within a specific piping system. Having the right size ensures a secure and leak-free connection, promoting smooth flow transition and optimal performance.

Manufacturers offer a wide range of sizes for 90 degree elbows, allowing you to find the perfect fit for your application. The most common sizes available in the market include 1/2 inch, 3/4 inch, 1 inch, 1-1/4 inch, 1-1/2 inch, and 2 inch. However, it’s important to note that these are just standard sizes, and custom sizes can also be manufactured to meet specific requirements.

In addition to size, the material of the 90 degree elbow is another crucial factor to consider. Different materials offer varying levels of strength, corrosion resistance, and durability. The choice of material should be based on the specific needs and characteristics of your piping system.

Some commonly used materials for 90 degree elbows include:

- PVC (Polyvinyl Chloride): PVC elbows are lightweight, easy to install, and resistant to corrosion and chemicals. They are commonly used in low-pressure applications and are available in various schedules.

- CPVC (Chlorinated Polyvinyl Chloride): CPVC elbows are ideal for hot water applications as they can withstand higher temperatures compared to PVC. They also offer excellent corrosion resistance.

- Stainless Steel: Stainless steel elbows are highly durable, corrosion-resistant, and suitable for both high and low-temperature applications. They are commonly used in industries where hygiene and cleanliness are crucial, such as pharmaceutical and food processing.

- Carbon Steel: Carbon steel elbows are known for their strength and durability. They are commonly used in high-pressure and high-temperature applications, such as oil and gas pipelines.

Factors to Consider When Selecting a 90 Degree Elbow

When choosing a 90 degree elbow for your piping system, there are several factors to take into consideration. These factors can help ensure that the elbow you select is the right fit for your specific application. Let’s explore these factors in more detail:

- Compatibility and Fit: It is important to select a 90 degree elbow that is compatible with the rest of your piping system. Consider the type of pipe material and size you are using, as well as the connection method (such as threaded, welded, or glued). Ensure that the elbow you choose is designed to connect seamlessly with your existing pipes.

- Pressure and Temperature: Another crucial factor to consider is the pressure and temperature requirements of your application. Different materials and sizes of 90 degree elbows have varying pressure and temperature ratings. Choose an elbow that can handle the specific pressures and temperatures your system will encounter to ensure long-lasting performance and safety.

- Chemical Compatibility: If your piping system transports fluids or gasses with corrosive properties, it is vital to select a 90 degree elbow made from a material that is chemically compatible with the substances being transported. Certain materials, such as stainless steel, are known for their excellent corrosion resistance, making them suitable for a wide range of chemical applications.

- Strength and Durability: Consider the strength and durability requirements of your piping system. For demanding applications or environments with high mechanical stress, a robust material like carbon steel may be a suitable choice. On the other hand, lighter materials like PVC or CPVC are often used in low-pressure applications or where corrosion resistance is a key consideration.

- Cost and Availability: Finally, it is important to factor in the cost and availability of the 90 degree elbow. Different materials and sizes may vary in price and availability. Ensure that the elbow you choose is within your budget and readily accessible when needed.

Conclusion

Understanding the dimensions of a 90 degree elbow is crucial for ensuring a secure and efficient piping system. By referring to a comprehensive elbow dimensions chart, you can determine the correct dimensions that will provide a compatible fit and optimal performance for your specific application.

The outside diameter, centerline radius, and wall thickness of a 90 degree elbow all play a significant role in creating a smooth flow transition, maintaining structural integrity, and ensuring a secure connection. It is important to consider these dimensions when selecting the right elbow for your piping system.

FAQs

What is a 90-degree elbow used for?

A 90-degree elbow is used to change the direction of flow in a piping system by 90 degrees, creating a right angle turn. It helps navigate around obstacles or change the direction of pipes efficiently.

What materials are 90-degree elbows made of?

90-degree elbows are available in various materials including PVC, copper, stainless steel, brass, and others. The choice of material depends on factors such as the type of fluid being transported, temperature, pressure, and compatibility with other materials in the system.

How do you install a 90-degree elbow?

Installation methods depend on the type of piping system and material used. For example, PVC elbows are typically solvent welded, while copper elbows may be soldered or brazed. Threaded elbows are screwed onto threaded pipe ends. Proper preparation of the pipe ends and application of appropriate sealants or adhesives are crucial for a secure and leak-free connection.

What sizes are 90-degree elbows available in?

90-degree elbows come in various sizes to accommodate different pipe diameters. Common sizes range from small diameters like 1/2 inch or 3/4 inch for residential plumbing to larger sizes used in industrial or commercial applications. The size of the elbow should match the diameter of the pipes being connected.

Can you use a 90-degree elbow for venting?

Yes, 90-degree elbows are commonly used in venting systems to change the direction of airflow. However, it’s important to follow building codes and standards to ensure proper installation and compliance with ventilation requirements.

Are there different types of 90-degree elbows?

Yes, there are different types of 90-degree elbows designed for specific applications. These include standard elbows, long radius elbows (with a larger radius for reduced friction and pressure drop), and short radius elbows (more compact, suitable for tight spaces but with higher pressure drop).

How do I calculate the pressure drop across a 90-degree elbow?

The pressure drop across a 90-degree elbow depends on factors such as the flow rate, fluid properties, elbow size, and type. Engineering handbooks or software can be used to calculate pressure drop based on these parameters.

Niketa Mulay, a seasoned content writer and editor, has over a decade of experience. With a Master’s in Journalism, she honed her skills at The Times of India and now freelances across various industries. Passionate about reading, writing, and scuba diving, she shares expert PDF guides and tips at PDFdrivehub.com.